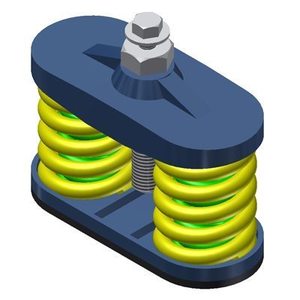

MERCER STAINLESS VEE ASSEMBLIES

Applications – Non-Seismic

- Fans

- Pumps

- Air Compressors

- Air Handling Units

Capacity

- 5kg – 18144kg

Deflection

- 25mm – 127mm

Options

- Height Saving Brackets

- Seismic Snubbers

- Bolted Base (SLF-H)

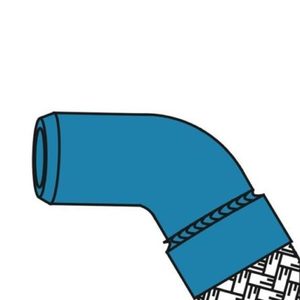

A vertical loop for pipework has always been a very useful and popular hose configuration and is still used in small diameters. If the radius is generous and considerably larger than the minimum bend radius. (i.e.: Hose forced into an arc less than the minimum bend radius takes a permanent set.) The configuration can move in many interesting ways as sketched. Commonly used for thermal expansion of large pipework runs or used as seismic loops at building joints removing thrust loads. The degree of motion is dependent on the diameter, length of live hose and the radius. Hoses that are more flexible because of more corrugations per metre, will accept greater displacements for a given configuration. It is not practical in the larger diameters as the bend radii become large and the configuration takes too much space, because of what is lost to the semicircle at the bottom. Our 60 degree Vee assemblies can be easily nested

304 SS can be used up to 454°C in applications such as engine exhaust. When using VFL products in copper or brass water or steam systems, dielectric flanges must be used on each end to prevent leakage from galvanic action.

We offer a complete range of vee assemblies for medical gas applications, supplied bagged and sealed.

Please consult your Mason Mercer representative for project specific assistance.

Applications

- Thermal Expansion Joints

- Seismic Movement Loops

- Building Movement Joints

Sizes

- 15mm – 600mm

Movement

- Up to 1200mm all direction

Options

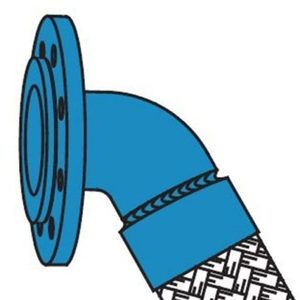

- VFL – Floating Flanges

- CSAVFL – Floating Flanges – CSA Aprroved

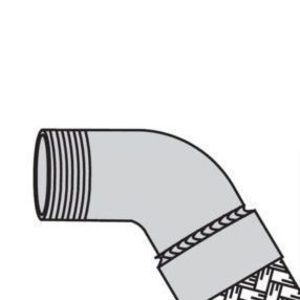

- VMN – Threaded Nipples

- CSAVMN – Threaded Nipples – CSA Approved

- VGN – Grooved Nipples

- CASVWN – Weld Nipples – CSA Approved

- VCPSB – Copper Sweat Ends. Option for Medical Gas

- VCPSB-UL – Copper Sweat Ends – UL Listed

Please contact your Mason Mercer representative to discuss your requirement prior to ordering to ensure correct selection.