Seismic Spring Mounts

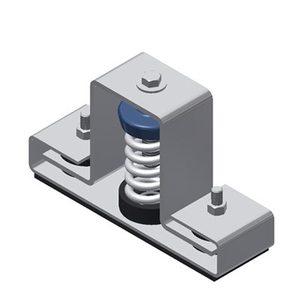

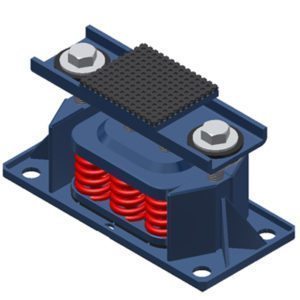

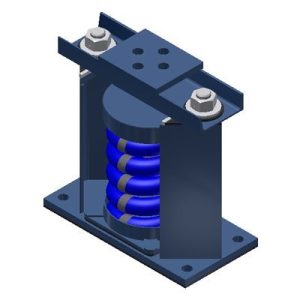

SSLFH-X Series Seismic Spring Mounts

Light duty seismically rated spring mount.

Applications – Seismic

- Fans

- Pumps

- Air Compressors

- Air Handling Units

Capacity

- 5kg – 95kg

Deflection

- 25mm

Options

- SAST Seismically Rated Anchors

Specification

Restrained spring mountings shall have an SSLFH-X mounting as described in SSLFH-X Specification, within a rigid housing that includes vertical limit stops to prevent spring extension when weight is removed. The housing shall serve as blocking during erection. Installed and operating heights are equal. Restraining Bolts shall have a neoprene bushing between the bolt and the housing. A clearance of 6mm shall be maintained around restraining bolts and the bushing so as not to interfere with the spring action. Limit stops shall be out of contact during normal operation. Since housings will be bolted or welded in position there must be an internal isolation pad. Housing shall be designed to resist all seismic forces. Mountings shall have an OPA pre-approval from OSHPD in the state of California certifying the maximum certified horizontal and vertical load ratings. Mountings shall be type SSLFH-X as manufactured by Mason Industries, Inc.

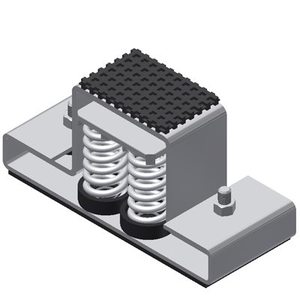

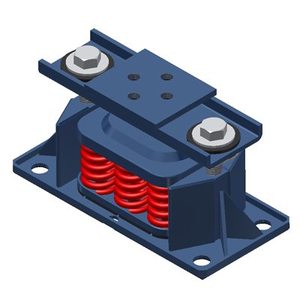

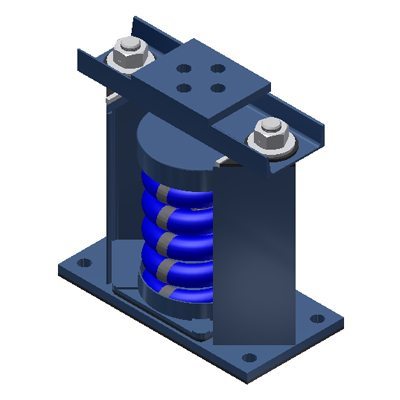

SLR-A Series Seismic Spring Mounts

Light to medium duty seismically rated spring mount. Low profile height – 130mm.

Compliant to AS1170.4

Applications – Seismic

- Fans

- Pumps

- Air Compressors

- Power Generators

- Chillers

- Air Handling Units

Capacity

- 20kg – 1136kg

Deflection

- 25mm

Options

- Addition Neoprene Isolation pad to top of mount

- SAST Seismically Rated Anchors

- Extended Base Plate (SLRAEBP)

- Stainless Steel

Specification

Restrained spring mountings shall have an SLR mounting as described in SLR Specification, within a rigid housing that includes vertical limit stops to prevent spring extension when weight is removed. The housing shall serve as blocking during erection. Installed and operating heights are equal. Restraining Bolts shall have a neoprene bushing between the bolt and the housing. A clearance of 6mm shall be maintained around restraining bolts and the bushing so as not to interfere with the spring action. Limit stops shall be out of contact during normal operation. Since housings will be bolted or welded in position there must be an internal isolation pad. Housing shall be designed to resist all seismic forces. Mountings shall have an OPA pre-approval from OSHPD in the state of California certifying the maximum certified horizontal and vertical load ratings. Mountings shall be type SLR as manufactured by Mason Industries, Inc.

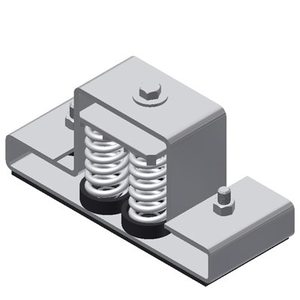

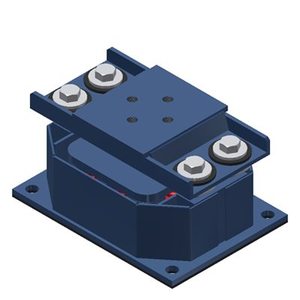

SLRSO Series Seismic Spring Mounts

Medium to heavy duty seismically rated spring mount. Adjustable Height. Compliant to AS1170.4Applications – Seismic

- Fans

- Pumps

- Air Compressors

- Power Generators

- Chillers

- Air Handling Units

Capacity

- 29kg – 10818kg

Deflection

- 25mm – 100mm

Options

- Extended Base Plates (SLRSOEBP)

- Addition Neoprene Isolation pad to top of mount

- Seismically Rated Anchor

Specification

Restrained spring mountings shall have an SLRSO mounting as described in SLRSO Specification, within a rigid housing that includes vertical limit stops to prevent spring extension when weight is removed. The housing shall serve as blocking during erection. Installed and operating heights are equal. Restraining Bolts shall have a neoprene bushing between the bolt and the housing. A clearance of 6mm shall be maintained around restraining bolts and the bushing so as not to interfere with the spring action. Limit stops shall be out of contact during normal operation. Since housings will be bolted or welded in position there must be an internal isolation pad. Housing shall be designed to resist all seismic forces. Mountings shall have an OPA pre-approval from OSHPD in the state of California certifying the maximum certified horizontal and vertical load ratings. Mountings shall be type SLRSO as manufactured by Mason Industries, Inc.

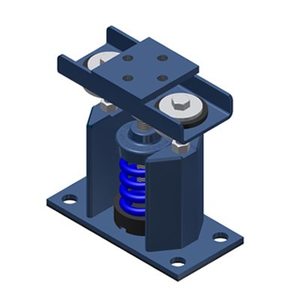

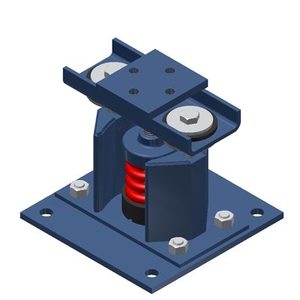

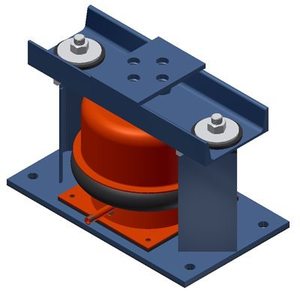

SLR 100 Series Seismic Spring Mounts

Light to ultra heavy duty high deflection seismically rated spring mount. Adjustable height. Compliant to AS1170.4. For use where a very low natural frequency of support is required.

Applications – Seismic

- Fans

- Pumps

- Air Compressors

- Power Generators

- Chillers

- Air Handling Units

Capacity

- 55kg – 18144kg

Deflection

- 50mm – 125mm

Options

- Addition Neoprene Isolation pad to top of mount

- Seismically Rated Anchor

Specification

Restrained spring mountings shall have an SLR mounting as described in SLR Specification, within a rigid housing that includes vertical limit stops to prevent spring extension when weight is removed. The housing shall serve as blocking during erection. Installed and operating heights are equal. Restraining Bolts shall have a neoprene bushing between the bolt and the housing. A clearance of 6mm shall be maintained around restraining bolts and the bushing so as not to interfere with the spring action. Limit stops shall be out of contact during normal operation. Since housings will be bolted or welded in position there must be an internal isolation pad. Housing shall be designed to resist all seismic forces. Mountings shall certify the maximum certified horizontal and vertical load ratings. Mountings shall be type SLRSas manufactured by Mason Industries, Inc.

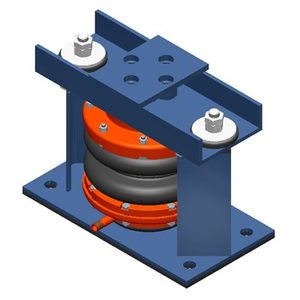

SLR-MT & SLR-MAS Series Seismic Air Spring Mounts

Light to heavy duty seismically rated air spring mount. Used in critical applications where very high levels of isolation are requiredApplications – Seismic

- Fans

- Pumps

- Power Generators

- Chillers

- MRI Machines

- Electron Microscopes

Capacity

- 136kg – 5455kg

Deflection

- SAST Seismically Rated Anchors

- Levelling Valve

- Micro Leveling Valvue

- Leveling Valve Stand

- Compressor

- Dryer and Filter

- Air Line Kit with Fittings

Specification

Seismic Air Springs shall be manufactured with upper and lower steel sections connected by a replaceable flexible nylon reinforced neoprene element. Air spring configuration shall be multiple bellows to achieve a maximum natural frequency of 3 Hz. Air Springs shall be designed for a burst pressure that is a minimum of three times the published maximum operating pressure. All air spring systems shall be connected to either the building control air or a supplementary air supply and equipped with three levelling valves to maintain levelling within plus or minus 1/8” (3mm). Submittals shall include natural frequency, load and damping tests performed by an independent lab or acoustician. Air Springs shall be type SLR-MT or SLR-MAS and levelling valves type LV as manufactured by Mason Industries, Inc.