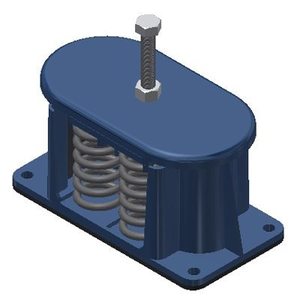

Type C Housed Spring Mounts

Applications – Non-Seismic

- Fans

- Pumps

- Air Compressors

- Air Handling Units

Capacity

- 5kg – 18144kg

Deflection

- 25mm – 127mm

Options

- Height Saving Brackets

- Seismic Snubbers

- Bolted Base (SLF-H)

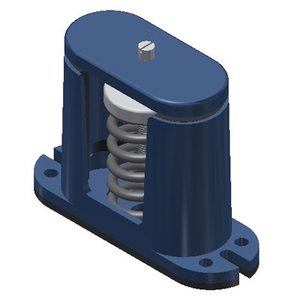

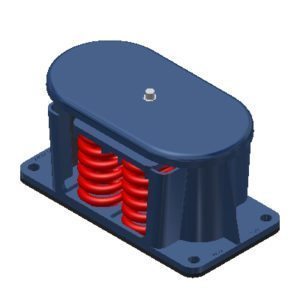

Type C Housed Spring Mounts

TYPE “C” Spring Mountings provide a packaged solution to troublesome vibration problems. Since the static deflection of the spring element is much greater than that provided by most rubber materials, these units will perform where it is necessary to establish low natural frequencies or to use a mounting that is more yielding than the supporting floor. Type “C” mountings are specifically designed for noise and vibration free application in critical areas on light concrete or wooden floors.

Semi-circular Neoprene sponge inserts limit movement during start and stop and prevent contact between the projections of the upper and lower semi-steel castings. These inserts are designed for a minimum of damping in all directions to allow the springs to function properly and develop installed efficiencies that are very close to the theoretical. Non-adjustable inserts are recommended for all air conditioning applications under compressors, air handling units, centrifugal fans and most other constant frequency vibration problems.

Applications – Non-Seismic

- Fans

- Pumps

- Air Compressors

- Air Handling Units

- Power Generators

Capacity

- 20kg – 11982kg

Deflection

- 25mm – 50mm

Options

- Height Saving Brackets

- Seismic Snubbers

Specification

Housed springs shall be manufactured with upper and lower semi-steel sections. Neoprene sponge inserts to be provided to limit movement during start stop and prevent contact between the projections of the upper and lower semi-steel castings. Housed Springs shall be type C as manufactured by Mason Industries, Inc.